二苯甲烷雙馬來醯亞胺是一種淺黃色粉末物品。

基本介紹

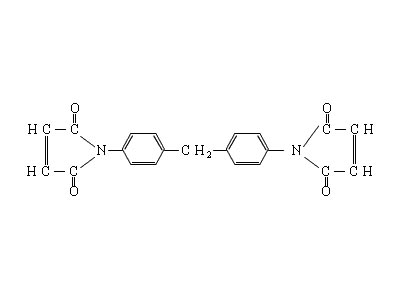

- 中文名:二苯甲烷雙馬來醯亞胺

- 外文名:N,N'--4,4'--DIPHENYLMETHANE--BISMALEIMIDE

- 分子量:358.37

- 熔點:152 ℃

- 水分:≤1%

基本信息,英文名,技術指標,優良性能,英文翻譯,

基本信息

英文名

N,N'--4,4'--DIPHENYLMETHANE--BISMALEIMIDE

二苯甲烷雙馬來醯亞胺

技術指標

◆外觀:淺黃色粉末

◆酸值:≤1.0 KOHmg/g

◆雜質: ≤0.1%

◆GT凝膠化時間:<3min (200℃,1克樣)

◆DSC數據: 聚合極限240℃±15℃; 聚合能 (△H)>200 J/g

◆固化物玻璃化溫度Tg: 340℃ (280℃/10 h固化)

◆固化物開始熱分解溫度Td: 空氣下開始失重溫度500℃ (280℃/10 h固化)

優良性能

本品能在高低溫(—200℃~260℃)下賦予材料突出的機械性能、高電絕緣性、耐磨性、耐老化及防化學腐蝕、耐輻射性、高真空中的難揮發性以及優良的粘結性、耐濕熱性和無油自潤滑性,是多種高分子材料及新型橡膠的卓越改性劑,還可作為其它高分子化合物的交聯劑、偶聯劑和固化劑等。

BMI套用領域:多年來,被稱為高溫下萬能塑膠的聚胺——雙馬來醯亞胺亦日趨廣泛地套用於高新技術的許多領域,主要有:一、電機絕緣材料 耐高溫浸漬漆(溶劑型和無溶劑型)、漆包線漆、層壓板、無緯帶、雲母帶、電子覆銅板、模壓塑膠、環氧改性F~H級粉末塗料、澆鑄件等;二、先進複合材料基體樹脂 航天、航空結構材料、碳纖維耐高溫結構件、高檔印刷線路板和其它功能材料等;三、工程塑膠 如聚丙烯PP、尼龍PA、ABS、APC、PVC、PBT、EPDM、PMMA等材料的增強改性劑(如在聚丙烯玻纖增強改性時加入<1%的BMI-01,即可使機械強度和馬丁耐熱提高一倍,效果顯著),還可用於新型橡膠硫化劑等;四、耐磨材料 金剛石砂輪、重負荷砂輪、剎車片、耐高溫軸承粘合劑、磁性材料等;五、其它方面 化肥生成(合成氨)機械設備的無油潤滑、動靜態密封材料等眾多高新技術領域。 BMI作為製造耐熱結構材料、H級或F級電氣絕緣材料的一種比較理想的樹脂基體,廣泛用於航空、航天、電力、電子、計算機、通訊、汽車、鐵路、建築等工業領域。

英文翻譯

N,N'-4,4'-Diphenylmethane--bismaleimide

Chemical Name: N,N’--4,4’—Diphenylmethane--bismaleimide(Short Form:BMI)

Molecular Formula: C21H14N2O4 Molecular Weight: 358.37Structural Formula: (1).Technical spec. of common type BMI-01: ▲Appearance: light yellow powder ▲M.P.: 150-157℃▲Acid Value: ≤3.0 KOHmg/g ▲Moisture: ≤1.0%▲Solubility in hot toluene: completely soluble ▲Impurity: ≤0.1%(2). Technical spec. of refined type BMI-01: ▲Appearance: light brilliant yellow powder ▲M.P.: 153-155℃▲Acid Value: ≤1.0 KOHmg/g ▲Moisture: ≤1.0%▲Solubility in hot toluene: completely soluble ▲Impurity: ≤0.1%▲GT (gelatinization time): <3min (200℃,1g sample)▲DSC data: limit of polymerization 240℃±15℃; polymerization energy(△H)>200 J/g▲Glass temperature of condensate, Tg: 340℃ (280℃/10 h solidifying)Thermal decomposition temp. of condensate, Td: weightlessness temp. in air: 500℃ (280℃/10 h solidifying)<2>Properties of BMI-01:1.Solubility: Soluble in dimethyl formamide, dimethyl acetamide, dimethyl sulfoxide etc.; partly soluble in acetone, dichloroethane and cresol. 2.Reactiveness:Can be copolymerized with many nucleophiles, such as amine, phenols, hydrogen sulphides and mercaptan. 3.Advantages of modified BMI-01: (1) Has similar viscoelasticity, rheological characteristic, moldability and workability to that of epoxy resins and thermosetting resins. (2)Won't release low-molecular volatile matter, and can used to make uniform heat-resistant materials and components without pores. (3)Has good compatibility with various fillers; has good wetting quality and ,adhesiveness with various fibers. (4)Good resistance to heat and moisture; low moisture absorption; can keep excellent mechanical property in dry, damp and high temperature (177-260℃) conditions. (5)Low factor of expansion, can achieve stable size of products. (6)Good resistance to radiation, low temperature, chemical reagents and wear. (7)Excellent dielectric property. (8)Lower price than polyimide.