由於表面玻化形成一定的顆粒強度,理化性能十分穩定,耐老化耐候性強,具有優異的絕熱﹑防火﹑吸音性能,適合諸多領域中作輕質填充骨料和絕熱﹑防火﹑吸音﹑保溫材料。在建材行業中,用玻化微珠作為輕質骨料,可提高砂漿的和易流動性和自抗強度,減少材性收縮率,提高產品綜合性能,降低綜合生產成本。

基本介紹

- 中文名:玻化微珠

- 優點:降低綜合生產成本

- 套用:填充骨料

- 性能:絕熱﹑防火﹑吸音

基本簡介

膨脹玻化微珠 | |

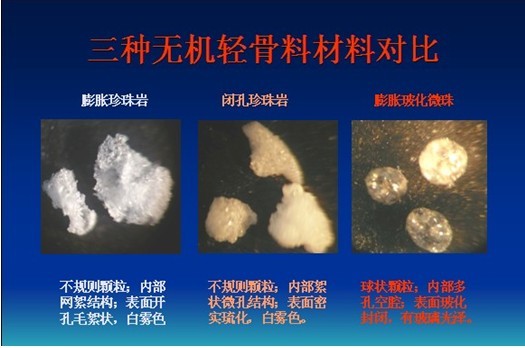

簡 述 膨脹玻化微珠是一種無機玻璃質礦物材料,經過多級碳化矽電加熱管式生產工藝技術加工而成,呈不規則球狀體顆粒,內部多孔空腔結構,表面玻化封閉,光澤平滑,理化性能穩定,具有質輕、絕熱、防火、耐高低溫、抗老化、吸水率小等優異特性,可替代粉煤灰漂珠、玻璃微珠、膨脹珍珠岩、聚苯顆粒等諸多傳統輕質骨料在不同製品中的套用。是一種環保型高性能新型無機輕質絕熱材料。 市面常見的三種無機材料對比與在乾混砂漿中的套用 |

名稱 Name | 原材料 Raw material | 物理性能 Physical Properties | 在砂漿中的套用 Application in Mortar |

膨脹珍 珠岩 Expanded perlite | 珍珠岩 Perlite | 1. 容重輕 (60~80kg/m3) 2.吸水率極大 3.顆粒強度低 4.導熱係數小 1. Low density 2.High water absorption 3.Low particle strength 4.Low heat conductivity | 1.不規則與毛絮狀的外形,容易在砂漿攪拌過程中產生阻力,和易性極差。 1. irregular and floccus, easy to make resistance while mixing, bad workability 2.容重輕,顆粒強度低,本身有較好的熱工性能,但在砂漿攪拌過程中容易破碎,會很大程度降低其熱工性能 2. Low density, low particle strength, good thermal property itself, but break easily while mixing, and reduce thermal property. 3.吸水率大,使得砂漿的需水量增加,破壞了砂漿的凝固周期,使得砂漿的力學性能大大降低,極易產生空鼓、開裂,嚴重影響整個保溫系統的熱工性能和耐久性。 3. High water absorption, which increase mortar water demand, degrade its mechanical property significantly, then easy to have hollowing and craze, has a strong impact on the thermal property and durability. |

閉孔珍珠岩 Hole-close perlite | 珍珠岩 Perlite | 1. 容重大 (120~180kg/m3) 2.吸水率較大 3.顆粒強度較大 4.導熱係數大 1. High density (120~180kg/m3) 2. High water absorption 3.High particle strength 4.High heat conductivity | 1.不規則的外形,在砂漿中易產生阻力,和易性差,攪拌時間長,造成其在砂漿中不易分布均勻,容易造成應力集中,引起空鼓、開裂,大大降低了砂漿的力學性能和熱工性能,也影響到保溫層的使用壽命。 1. irregular shape makes it easy to produce resistance, low workability, long mixing time, makes it unevenly distributed in the mortar, which will easy cause stress concentration, hollowing and cracking, reduce mechanical property and thermal property greatly, also has impact on the insulation layer service life. 2.容量大,導熱係數較差,在砂漿中必須增加輕骨料摻加比列方能滿足熱工性能標準要求,輕骨料摻加量的增加必然會降低砂漿的力學性能或增加膠凝材料成本。 2. High capacity with bad heat conductivity, need to increase light aggregate to meet the thermal property requirement, but adding light aggregate will reduce mortar mechanical property and increase gelled materials cost. 3.吸水率較大,在套用過程中會出現上述膨脹珍珠岩同樣的問題,不過在各項指標上要優於膨脹珍珠岩。 3. High water absorption, will have similar problems as expanded perlite while using, but have better performance than expanded perlite. |

膨脹玻化微珠 Expanded and vitrified small ball | 松脂岩 Perlite | 1. 容重輕(80~120kg/m3) 2.吸水率小 3.顆粒強度較大 4.導熱係數小 1. Low density (80~120kg/m3) 2.Low water absorption 3.High particle strength 4.Low heat conductivity | 1.球狀顆粒,表面玻化,在砂漿攪拌工程中流動性好,和易性佳,能在短時間內攪拌均勻,降低了砂漿在乾濕攪拌過程中的骨料破碎,有穩定的熱工性能與力學性能。 1. Spherical particle, surface vitrified, good fluidity while mixing, good workability, mixed evenly shortly, then reduce the aggregate broke when dry-wet mixing, good thermal property and mechanical property. 2.容量輕,導熱係數低 2. low density, light weight, low heat conductivity 3.吸水率小,很容易在砂漿中得到控制,收縮率小,不空鼓開裂,有穩定的熱工性能與力學性能,並且也相對提高了砂漿的使用壽命。 3. Low water absorption, easily controlled in mortar, low shrinkage, no hollowing and cracking, stable thermal property and mechanical property, increase the mortar service life. |

理化特徵 導熱係數小、質輕(容重較小)low heat conductivity, light weight(low density) 防火、耐高、低溫 fire proof, temperature resistance 抗老化 ageing resistance 吸水率小 low water absorption 性能穩定 stable property 環 保 environmental friendly 材料組成及結構 無機玻璃質礦物材料 mineral glass nature material 呈不規則球狀顆粒 irregular sphere granula 內部呈多孔空腔結構 porus microchamber inside 表面玻化封閉、平滑、有光澤 surface vitrified close, smooth, luster  玻化微珠的物理性能 |

項目Item | I 類 | II 類 | III 類 |

堆積密度/kg/m3 Bulk density | <80 | <80~120 | > 120 |

筒壓強度/kPa Cylindrical compress strength | ≥50 | ≥150 | ≥200 |

導熱係數/W/(m·K)平均溫度25℃ Heat conductivity Average temperature 25℃ | ≤0.043 | ≤0.048 | ≤0.070 |

體積吸水率/% Volatile water absorption | ≤45 | ||

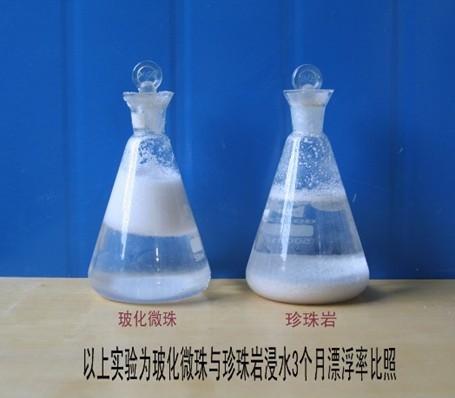

體積漂浮率/% Volume floating rate | ≥80 | ||

表面玻化閉孔率/% Surface vitrified close cell content | ≥80 | ||

應 用 可替代粉煤灰漂珠、玻璃微珠、膨脹珍珠岩、聚苯顆粒等諸多傳統輕質骨料,套用於工業、農業、化工、冶金、建材等諸多領域。 It can be substitute of lightweight aggregates such as fly ash floating bead, glass microbaloon, expanded perlite, expanded polystyrene granule, and has application in areas as industry, agriculture, chemical industry, metallurgy, construction and so on. |

性能分析

適用範圍

系統特點

規格尺寸

乾粉砂漿

保溫砂漿

項目 | 技術要求 | |

Ⅰ型 | ||

乾密度∕(kg/m) | 240~300 | 301~400 |

抗壓強度∕Mpa | ≥0.20 | ≥0.40 |

導熱係數(25℃)(W∕(m.K) | ≤0.070 | ≤0.0850 |

線收縮率∕% | ≤0.30 | ≤0.30 |

壓剪粘結強度∕ | ≥50 | ≥50 |

燃燒性能級別 | A1級 | |