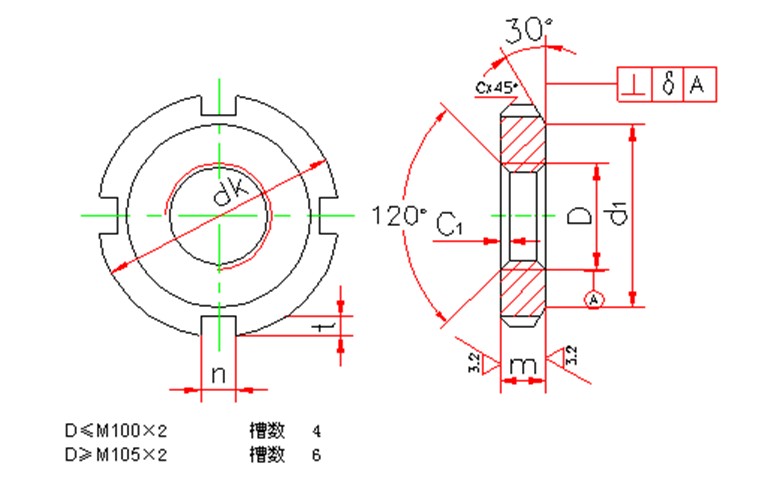

圓螺母常與圓螺母用止動墊圈配用,裝配時將墊圈內舌插入軸上的槽內,而將墊圈的外舌嵌入圓螺母的槽內,螺母即被鎖緊。常作為滾動軸承的軸向固定。螺紋規格為M10×1~M200×3的圓螺母。

螺紋規格D=M16×1.5、材料為45鋼、槽或全部熱處理後硬度HRC35~45、表面氧化的圓螺母的標記:螺母 GB/T 812-88 M16×1.5。

基本介紹

- 中文名:圓螺母

- 所屬類目:機械零件

- 分類:標準件

- 螺紋規格:M10×1~M200×3

螺紋規格 D×P | dk | d1 | m | n | t | C | C1 | ||

max | min | max | min | ||||||

M10×1 | 22 | 16 | 8 | 4.3 | 4 | 2.6 | 2 | 0.5 | 0.5 |

M12×1.25 | 25 | 19 | 8 | 4.3 | 4 | 2.6 | 2 | 0.5 | 0.5 |

M14×1.5 | 28 | 20 | 8 | 4.3 | 5 | 2.6 | 2 | 0.5 | 0.5 |

M16×1.5 | 30 | 22 | 8 | 5.3 | 5 | 3.1 | 2.5 | 0.5 | 0.5 |

M18×1.5 | 32 | 24 | 8 | 5.3 | 5 | 3.1 | 2.5 | 0.5 | 0.5 |

M20×1.5 | 35 | 27 | 8 | 5.3 | 5 | 3.1 | 2.5 | 0.5 | 0.5 |

M22×1.5 | 38 | 30 | 10 | 5.3 | 5 | 3.1 | 2.5 | 1 | 0.5 |

M24×1.5 | 42 | 34 | 10 | 5.3 | 5 | 3.1 | 2.5 | 1 | 0.5 |

M25×1.5 | 42 | 34 | 10 | 5.3 | 5 | 3.1 | 2.5 | 1 | 0.5 |

M27×1.5 | 45 | 37 | 10 | 5.3 | 5 | 3.1 | 2.5 | 1 | 0.5 |

M30×1.5 | 48 | 40 | 10 | 5.3 | 5 | 3.1 | 2.5 | 1 | 0.5 |

M33×1.5 | 52 | 43 | 10 | 6.3 | 6 | 3.6 | 3 | 1 | 0.5 |

M35×1.5 | 52 | 43 | 10 | 6.3 | 6 | 3.6 | 3 | 1 | 0.5 |

M36×1.5 | 55 | 46 | 10 | 6.3 | 6 | 3.6 | 3 | 1 | 0.5 |

M39×1.5 | 58 | 49 | 10 | 6.3 | 6 | 3.6 | 3 | 1.5 | 0.5 |

M40×1.5 | 58 | 49 | 10 | 6.3 | 6 | 3.6 | 3 | 1.5 | 0.5 |

M42×1.5 | 62 | 53 | 10 | 6.3 | 6 | 3.6 | 3 | 1.5 | 0.5 |

M45×1.5 | 68 | 59 | 10 | 6.3 | 6 | 3.6 | 3 | 1.5 | 0.5 |

M48×1.5 | 72 | 61 | 12 | 8.36 | 8 | 4.25 | 3.5 | 1.5 | 0.5 |

M50×1.5 | 72 | 61 | 12 | 8.36 | 8 | 4.25 | 3.5 | 1.5 | 0.5 |

M52×1.5 | 78 | 67 | 12 | 8.36 | 8 | 4.25 | 3.5 | 1.5 | 0.5 |

M55×2 | 78 | 67 | 12 | 8.36 | 8 | 4.25 | 3.5 | 1.5 | 0.5 |

M56×2 | 85 | 74 | 12 | 8.36 | 8 | 4.25 | 3.5 | 1.5 | 1 |

M60×2 | 90 | 79 | 12 | 8.36 | 8 | 4.25 | 3.5 | 1.5 | 1 |

M64×2 | 95 | 84 | 12 | 8.36 | 8 | 4.25 | 3.5 | 1.5 | 1 |

M65×2 | 95 | 84 | 12 | 8.36 | 8 | 4.25 | 3.5 | 1.5 | 1 |

M68×2 | 100 | 88 | 12 | 10.36 | 10 | 4.75 | 4 | 1.5 | 1 |

M72×2 | 105 | 93 | 15 | 10.36 | 10 | 4.75 | 4 | 1.5 | 1 |

M75×2 | 105 | 93 | 15 | 10.36 | 10 | 4.75 | 4 | 1.5 | 1 |

M76×2 | 110 | 98 | 15 | 10.36 | 10 | 4.75 | 4 | 1.5 | 1 |

M80×2 | 115 | 103 | 15 | 10.36 | 10 | 4.75 | 4 | 1.5 | 1 |

M85×2 | 120 | 108 | 15 | 10.36 | 10 | 4.75 | 4 | 1.5 | 1 |

M90×2 | 125 | 112 | 18 | 12.43 | 12 | 5.75 | 5 | 1.5 | 1 |

M95×2 | 130 | 117 | 18 | 12.43 | 12 | 5.75 | 5 | 1.5 | 1 |

M100×2 | 135 | 122 | 18 | 12.43 | 12 | 5.75 | 5 | 1.5 | 1 |

M105×2 | 140 | 127 | 18 | 12.43 | 12 | 5.75 | 5 | 1.5 | 1 |

M110×2 | 150 | 135 | 18 | 14.43 | 14 | 6.75 | 6 | 1.5 | 1 |

M115×2 | 155 | 140 | 22 | 14.43 | 14 | 6.75 | 6 | 1.5 | 1 |

M120×2 | 160 | 145 | 22 | 14.43 | 14 | 6.75 | 6 | 1.5 | 1 |

M125×2 | 165 | 150 | 22 | 14.43 | 14 | 6.75 | 6 | 1.5 | 1 |

M130×2 | 170 | 155 | 22 | 14.43 | 14 | 6.75 | 6 | 1.5 | 1 |

M140×2 | 180 | 165 | 26 | 14.43 | 14 | 6.75 | 6 | 1.5 | 1 |

M150×2 | 200 | 180 | 26 | 16.43 | 16 | 7.9 | 7 | 1.5 | 1 |

M160×3 | 210 | 190 | 26 | 16.43 | 16 | 7.9 | 7 | 2 | 1.5 |

M170×3 | 220 | 200 | 26 | 16.43 | 16 | 7.9 | 7 | 2 | 1.5 |

M180×3 | 230 | 210 | 30 | 16.43 | 16 | 7.9 | 7 | 2 | 1.5 |

M190×3 | 240 | 220 | 30 | 16.43 | 16 | 7.9 | 7 | 2 | 1.5 |

M200×3 | 250 | 230 | 30 | 16.43 | 16 | 7.9 | 7 | 2 | 1.5 |