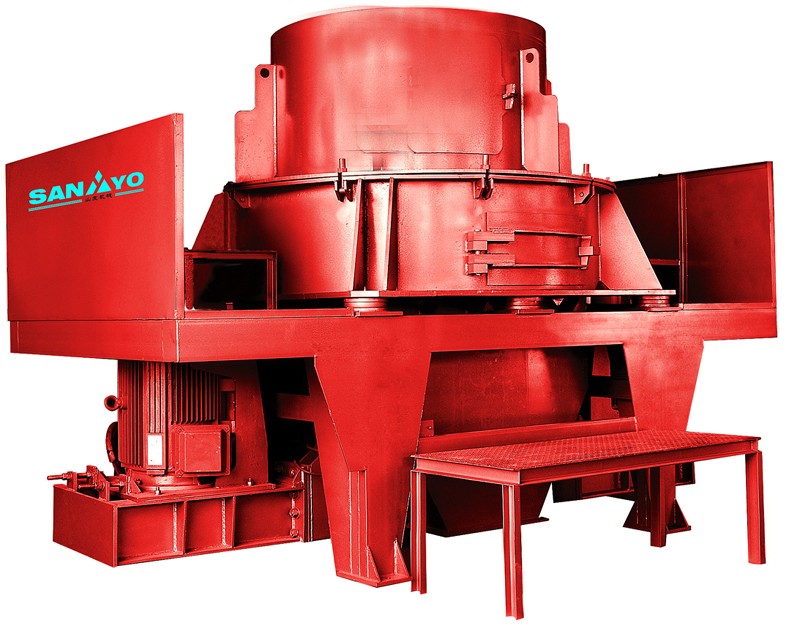

vertical shaft impact crusher即立軸反擊式破碎機,也被稱為制砂機,廣泛用於礦物和非金屬礦石,耐火材料,鋁土礦,鑽石粉,玻璃原料,建築材料,人造砂和各種金屬的礦物產品的粉末工藝中礦石材料,尤其是在加工更多和最堅硬的材料方面比其他任何機器都更具優勢的材料。

基本介紹

- 中文名:vertical shaft impact crusher

- Little:noise and dust pollution

- Simpl:structure, low cost

- Primary:crushing capacity

簡介,內容,

簡介

Vertical shaft impact crusher also know as sand making machine is applied widely for the powder process of mineral product including mental and non-metal ore, fireproof material, bauxite, diamond dust, glass raw materials, architectural materials, artificial sand and all kinds of metal ore materials, especially which has more advantages than any other machines in processing the more and most hard materials.

Application

vertical shaft impact crusher

Features and Benefits

* Simple structure, low cost

* High efficiency and low consumption

* Primary and second crushing capacity

* More and most hard materials can be crushed

* Cubic shaped final product

* Little noise and dust pollution

* Convenient performance, maintenance, installation

Working Principle

The Whole PCL vertical shaft impact crusher including feed hopper, classifier, whirl pool cacity, impeller, main bearing assembly base, transmission device and motor etc.

內容

Operating principle is as follows: the materials enter the crusher through feeder hopper, which is divided into two parts, one part through the middle of classifier entering into the rotating impeller at high speed, then accelerated, whose speed can reach hundreds of acceleration, then is shot through the tunnels around the impeller by the speed of 60-75 meter/second. First the materials will impact with some materials fallen around classifier, then impact on the whirlpool cavity's scaleboard together, then will be rebounded and impact on the top of the whirlpool cavity, then changes its direction and goes down, forms continual material layers with the materials shot from the impeller. Therefore some materials will be impacted, crusher, milled twice or more times in the whirlpool cavity, then crushed materials will be excluded through the bottom discharging hole. This can from a closed circulation through the circular classifier system; in general, materials can be crushed into 20 mesh through thrice circulation. Airflow self-circulation in the whirlpool cavity can eliminate the dust pollution well.